System Lift Capacities Explained: Why They Issue for Lift Servicing

Wiki Article

Professional Tips for Ensuring Safety And Security During Comprehensive Lift Fixing Procedures

In the realm of thorough lift repair service procedures, safety and security stands as a critical concern that demands precise focus to detail and adherence to developed procedures. As the intricate interplay of machinery and human treatment unravels, a calculated method to safety ends up being the linchpin for effective repair procedures.Safety Equipment Requirements

The safety and security gear demands for lift repair treatments are important to make certain the well-being of maintenance employees. Appropriate safety and security gear not just shields workers from prospective threats but additionally enhances effectiveness and accuracy throughout repair tasks. When servicing lifts, maintenance employees must abide by stringent safety and security protocols by wearing proper equipment such as construction hats, security goggles, handwear covers, steel-toed boots, and high-visibility vests. These things are made to provide security against head injuries, eye damages, hand injuries, foot injuries, and improve exposure in the job environment to avoid mishaps.Security goggles shield the eyes from debris, chemicals, or sparks that might be produced during fixing work. By strictly sticking to security gear needs, upkeep employees can minimize risks and job effectively to maintain and fix lifts.

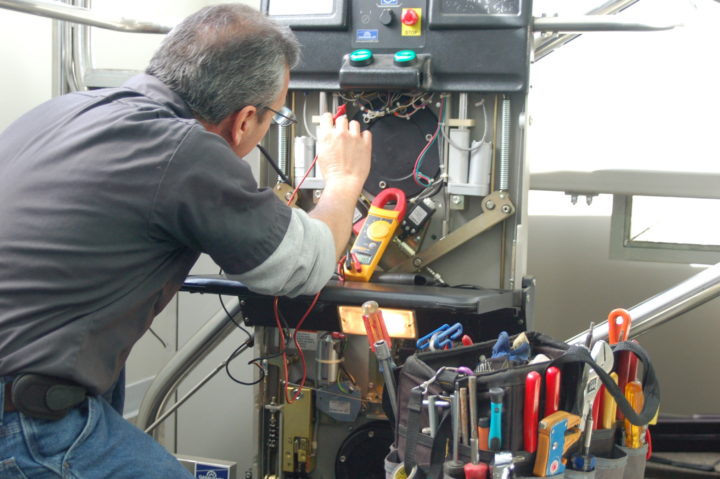

Devices Examination List

To make certain the maintenance personnel's safety and the proper functioning of lifts, a thorough devices assessment checklist is necessary before starting any kind of fixing procedures. lift repair. This list must include a complete assessment of all elements such as cable televisions, sheaves, electrical systems, and safety and security systems. It is critical to evaluate for any type of indications of wear and tear, corrosion, or damages that might jeopardize the lift's structural integrity or functional effectivenessAlong with mechanical components, the examination list ought to incorporate security features like emergency situation brakes, limitation switches, and overload sensing units. These security mechanisms play an essential role in guaranteeing and preventing crashes individual defense throughout lift procedure.

Moreover, verifying the calibration of control systems, confirming correct ventilation and lights within the lift shaft, and checking for any type of blockages or debris are necessary action in the assessment procedure. Regular maintenance and adherence to the tools examination checklist not only improve safety and security protocols however additionally extend the lifespan of the lift system, reducing the probability of pricey repair work or unforeseen failings.

Hazard Recognition Techniques

Using organized evaluation techniques, hazard recognition methods are utilized to pinpoint possible dangers within lift repair work treatments. One typical technique is the Work Safety And Security Analysis (JSA), where each action of the repair service process is carefully assessed to determine potential dangers and identify the ideal safety steps to minimize them.

Emergency Response Readiness

With a focus on guaranteeing swift and effective response to unanticipated circumstances, emergency response readiness is an important aspect of maintaining safety and from this source security throughout lift repair treatments. Prioritizing emergency readiness involves developing clear communication networks, assigning specific duties and obligations, and conducting normal drills to test feedback times and procedures.Key components of emergency reaction readiness include having conveniently easily accessible emergency treatment kits, fire extinguishers, and emergency situation get in touch with details prominently showed. It is essential to educate all personnel associated with lift repair treatments on emergency action protocols, including just how to safely evacuate the location in instance of a fire or various other emergencies.

In addition, developing an extensive emergency situation reaction plan details to raise repair work situations can help reduce prospective threats and ensure a timely and worked with response in the occasion of a case. Routinely updating this plan and evaluating based on lessons picked up from past drills or events is necessary to continually boost precaution during lift repair work procedures.

Ongoing Security Training

Constant education and learning and training in safety protocols is a fundamental part of ensuring the continuous safety of personnel throughout lift fixing procedures. Ongoing safety and security training plays a critical role in maintaining workers notified regarding the most current security requirements, procedures, and best practices in the sector (platform lift dimensions). By supplying normal training sessions, employees can remain updated on potential hazards, secure job procedures, and emergency methods certain to lift repair work environmentsNormal safety and security training likewise helps enhance the value of complying with safety standards and treatments whatsoever times. Learn More It instills a safety-conscious frame of mind amongst employees, promoting a society of security within the office. In addition, ongoing training enables workers to refresh their expertise and skills, boosting their preparedness to take care of any type of unforeseen safety and security difficulties that may arise throughout lift fixing procedures.

To guarantee the performance of continuous safety and security training, it is important to customize the web content to the certain threats and requirements related to lift repair service procedures - lift breakdown. Employers ought to frequently analyze training needs, supply opportunities for hands-on method, and motivate open communication regarding security problems among all workers included in lift fixing operations

Final Thought

In verdict, ensuring security throughout comprehensive lift repair service treatments is vital for stopping crashes and injuries. By following safety and security equipment requirements, conducting equipment assessments, determining threats, planning for emergencies, and providing ongoing safety training, click workers can lessen dangers and produce a risk-free workplace. Focusing on precaution and remaining cautious throughout the fixing procedure will certainly aid shield both employees and the tools being serviced.When functioning on lifts, maintenance workers should adhere to strict safety methods by putting on ideal equipment such as difficult hats, security goggles, gloves, steel-toed boots, and high-visibility vests. One common strategy is the Work Safety And Security Analysis (JSA), where each step of the repair procedure is meticulously examined to determine prospective hazards and determine the ideal safety and security procedures to reduce them.Continuous education and training in safety and security methods is an essential component of making certain the recurring safety of personnel throughout lift repair service procedures.Regular safety and security training likewise helps enhance the value of following safety and security guidelines and treatments at all times. By complying with safety equipment demands, performing devices evaluations, recognizing risks, preparing for emergency situations, and supplying ongoing security training, employees can reduce risks and produce a secure work setting.

Report this wiki page